- May 15, 2024

- LiveStrong Technologies

- 0

What is NetSuite Manufacturing?

NetSuite Manufacturing is meant for manufacturers who wish to streamline their operations, become more efficient and monitor their overall production process better. It can be used in many different manufacturing sectors including discrete manufacturing, process manufacturing and mixed-mode manufacturing.

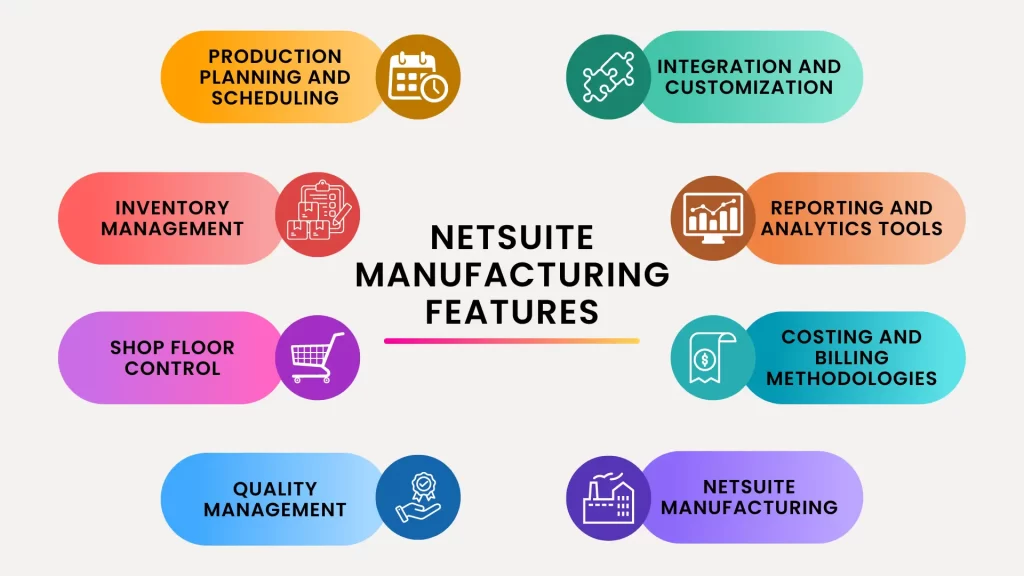

NetSuite Manufacturing Features

1. Production Planning and Scheduling:

NetSuite manufacturing has tools for demand forecasting, material requirement planning (MRP), capacity planning and production scheduling which help manufacturers optimally plan their productions while ensuring they have the right resources at the right time.

2. Inventory Management:

3. Shop Floor Control:

A variety of toolkits are embedded in NetSuite Manufacturing to run shop floor operations such as work order management, labor tracking and machine scheduling for workflow monitoring as well as supervision on factory floors so that it can control work movement.

4. Quality Management:

This solution supports quality assurance processes such as non-conformance management, CAPA (Corrective/Preventative action) procedures, quality inspections among others which guide clients on how to achieve stable high-quality goods in line with industry benchmarks.

5. NetSuite Manufacturing:

For Supply Chain Management is integrated with other NetSuite modules like inventory control, procurement and demand planning to offer a total view of the supply chain.

6. Costing and Billing Methodologies:

The manufacturing solution covers standard, average and actual costs. Similarly, revenue recognition is supported in addition to project-based billing for manufacturers who work on long-term projects or contracts.

7. Reporting and Analytics Tools:

There are standard reports as well as various dashboards which are ready-made while some ad-hoc reporting tools serve the purpose of data analysis by manufacturers in formulating their business decisions.

8. Integration and Customization (NetSuite Manufacturing):

This is cloud based software hence easily scalable to integrate it with other enterprise systems with custom features designed to suit particular industry requirements.

NetSuite Manufacturing addresses several key challenges faced by manufacturers, including:

• Complex Production Planning and Scheduling:

NetSuite makes available a comprehensive planning and scheduling tool with robust Material Requirements Planning (MRP), Master Production Scheduling (MPS), Capacity Planning, and Finite Scheduling. This ensures that they effectively plan their production schedules properly ensuring that materials and resources are always available when required.

• Inventory Management Complexities:

With functions like lot or serial number traceability, cycle counting, bin management, and multi-location inventory tracking, NetSuite supports manufacturers in maintaining accurate inventory levels and visibility throughout the supply chain.

• Quality Control and Compliance Issues:

Integrated quality management capabilities are part of NetSuite Manufacturing such as non-conformance management, corrective and preventive actions (CAPA), quality inspections, supplier quality management among others which help manufacturers maintain consistent product quality while conforming to industry standards & regulations.

• Lack of Visibility in the Supply Chain:

NetSuite Manufacturing integrates with other modules such as inventory management and demand planning to ensure a complete oversight and control of the supply chain. This will enhance manufacturers’ relationship with suppliers, while managing market changes, optimizing their supply chains.

• Inaccurate Costing and Billing:

In NetSuite Manufacturing you can choose between standard, average or actual costing. Additionally, it includes project-based billing as well as revenue recognition functions that guarantee correct costing, profitability analysis and billing for manufacturers who engage in long-term projects or contracts.

• Lack of Real-Time Data and Reporting:

NetSuite manufacturing has real-time dashboards as well as operational KPIs on-demand reporting and a set of built-in manufacturing reports which enable quick up-to-minute insights to decision making through data-analytics.

• Silos of Data and Systems:

NetSuite Manufacturing software can be easily connected to other business applications and personalized to the specific needs because it is a cloud-based solution. It helps manufacturers in the process of demolishing data silos and achieving more holistic integration across their system as well as processes.

• Challenges with Regulatory Compliance:

Lot traceability, dangerous materials management, and industry-specific compliance (e.g., FDA, GMP) support are among NetSuite Manufacturing features. These functions aid in making sure that manufacturers comply with the relevant regulations set by different authorities.

• The Ineffective Shop Floor Operations:

NetSuite Manufacturing provides tools such as work order management, labor tracking, machine scheduling, mobility, all aimed at streamlining shop floor operations through improved efficiency and productivity.

Key Benefits of using NetSuite Manufacturing:

1. Enhanced Operational Efficiency:

- Streamlined manufacture planning, scheduling, and execution processes

- Enhanced stock control and material traceability

- Automated workflows and real time data update cross the operations

2.Better Inventory Management:

- Precise stock keeping across different locations

- Lot and serial number follow-up

- Reduced carrying costs but with improved inventory turns.

3.Improved Quality Control:

- Integrated quality management systems

- Non-conformance tracking and corrective actions

- Supplier quality management and compliance support.

4.Enhanced Supply Chain Visibility:

- Complete supply chain visibility.

- Demand forecasting and planning options.

- Supplier relationship management solutions offered.

5.Cost Control and Profitability:

- Accurate costing using standard, average, actual costing methods.

- Overhead cost allocation & roll up capabilities.

- Project oriented billing & revenue realization.

6.Scalability and Flexibility:

- Cloud-based strategy is adopted so that it can be easily scalable

- Customizable to fit the specific needs of business

- Interfaced with other NetSuite modules and 3rd party systems.

7.Real-Time Insights and Reporting:

- Real-time dashboards and KPIs for operational performance

- Want to perform ad hoc reporting and querying on data for analysis

- Built-in manufacturing reports as well as analytics.

8.Mobility and Remote Access:

- Mobile accessibility for doing transactions while moving

- Seamlessly integrated with IoT, automation systems, etc.,

- Anytime anywhere access to Data and Processes.

9.Regulatory Compliance:

- Lot traceability, hazardous materials management,

- Support FDA, GMP, and other industry-specific compliance requirements;

- Environmental compliance management capabilities.

10.Lower IT Costs:

- Infrastructure costs are reduced through cloud deployment.

- Automatic software updates/upgrades are available

- IT overhead/maintenance is minimized.

Frequently Asked Questions (FAQs)

NetSuite Manufacturing supports various manufacturing modes, including discrete manufacturing, process manufacturing, and mixed-mode manufacturing.

NetSuite Manufacturing provides robust inventory management capabilities, including multi-location inventory tracking, lot and serial number traceability, bin management, cycle counting, and automated replenishment.

NetSuite Manufacturing includes features for quality management, such as non-conformance management, corrective and preventive actions (CAPA), quality inspections, and supplier quality management.

NetSuite Manufacturing supports various costing methods, including standard, average, and actual costing, as well as overhead cost allocation and cost roll-up capabilities for accurate profitability analysis.

Yes, NetSuite Manufacturing supports project-based manufacturing, including project-based billing, revenue recognition, and cost roll-up capabilities.