- May 15, 2024

- LiveStrong Technologies

- 0

What is Inventory Management?

Inventory management entails overseeing and controlling the ordering, storage, and usage of a company’s inventory. The main objective of inventory management is to make sure that the right products are available at the right place at the right time while minimizing costs. Effective inventory management monitors levels of stock, determines reorder quantities and points, tracks product movement, plans for replenishment and reconciles discrepancies. It therefore optimizes investment in inventories, maximizes stock utilization rate, enhance order fulfillment as well as reducing carrying costs of inventories and obsolescence risks.

What is NetSuite Inventory Management?

NetSuite Inventory Management is an internet-based inventory management solution that NetSuite offers. It enables a company to follow their stock levels, movements and value in various locations from one location. Among its characteristics are; handling of stocks at different sites, managing and optimizing inventory, calculating landed costs, planning cycle counts and inventory counts, serializing commodities by lot number etc., thereby integrating it with the supply chain and manufacturing processes.

It provides real-time visibility into inventory status for businesses together with automated reorder point calculations, valuation of inventory and suggested replenishment based on demand forecasting. With it the firm always has right stock quantities at all times hence minimizing holding costs as well as meeting customer requirements efficiently.

Types of Inventory Management

1. The stock is checked continuously. The data can be viewed in real time. For example, it uses bar coding, RFID or wireless inventory tracking systems to update the inventory records after every transaction.

2. An example of periodic inventory management includes annual and monthly physical counts for updating the inventory records.

3. Additionally, ABC inventory control system classifies the items into three forms which are A (high value), B (medium value) and C (low value) based on certain criteria like cost, sales and usage thereby channeling efforts to those vital materials or goods.

4. In order to minimize storage costs as well as carrying costs, stocks that are needed for production or resale are received just before they are required; hence ensuring that they do not stay in stores for long periods until there is demand from customers who want them urgently.

5. It involves processing Master Production Schedule (MPS): Bill of Materials (BOM) data with an aim of determining the quantity and timing of finished products’ components and materials required by a manufacturing firm at different points in time.

6. Distribution requirement planning allows one to know how much stock to keep at each distribution center based on expected demand across the entire supply chain network.

7. The economic order quantity determines minimum reorder level so that ordering costs are equal to carrying costs therefore minimizing total cost of holding inventory.

Key Challenges Faced by Inventory Management

1. To keep the right stock levels and avoid overstocking or understocking, it is important to predict customer demand accurately.

2. When suppliers lead time vary, inventory planning gets affected and results in stock out or over stocking.

3. This implies handling a diverse range of merchandise that varies in terms of demand patterns as well as life cycles.

4. It deprives supply chain stakeholders of accessing real time inventory information regarding quantities, movement and location along the supply chain.

5. Due to mistakes during manual processing, there is inaccurate data in inventories leading to poor decision-making processes.

6. Limiting loses coming from expired, obsolete or spoiled products reduces costs incurred by businesses.

7. Therefore they should minimize their storage area whilst reducing carrying expenses linked with maintaining goods within it.

8. The firm will have to adjust its operations following disruptions due to natural catastrophes, strikes among others which impact other countries’ economic growth rates.

9. As much as possible firms need to reduce thefts, errors made by employees while recording stocks and also dishonest supply partners responsible for this shrinkage.

10. The coordination of multiple sales channels and fulfillment centers necessitates multi-channel and omni-channel fulfillment; all customers can be served through any channel available at a given point in time.

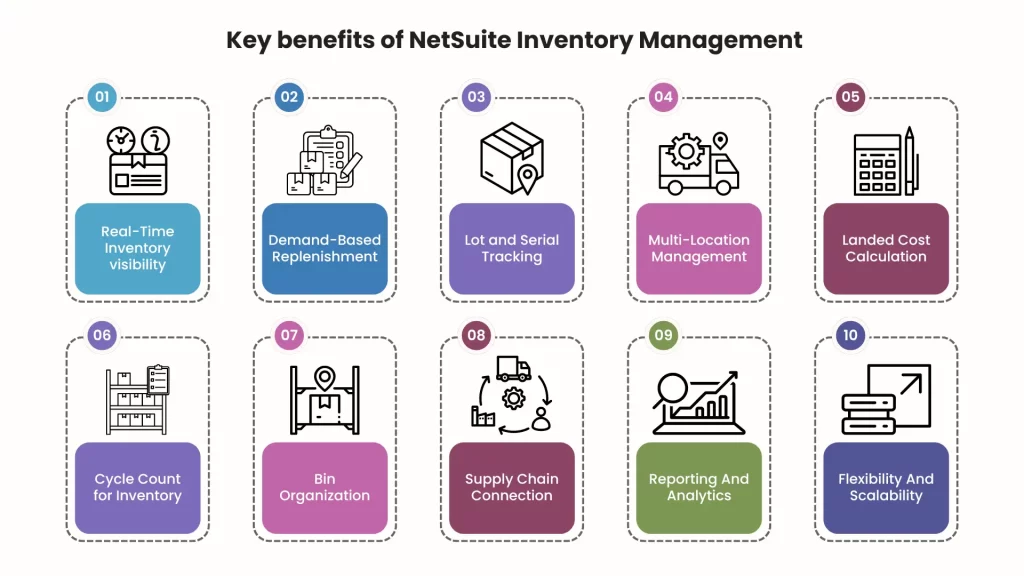

Key Benefits of NetSuite Inventory Management

• Real-Time Inventory visibility:

This is possible because NetSuite provides real-time information on stock levels, their fluctuation presently and how much they are worth within various branches.

• Demand-Based Replenishment:

By using the demand forecasting tool, NetSuite can provide recommendations for reordering stocks automatically to keep optimum inventory levels.

• Lot And Serial Tracking:

For instance, it allows tracking of batch numbers, expiry dates and serial numbers for traceability purposes as well as compliance with regulations.

• Multi-Location Management:

In other words, this implies that different warehouses, stores or drop shippers are just brought together under one platform.

• Landed Cost Calculation:

In computing true landed cost of goods sold by NetSuite, such expenses include shipping costs, duties/taxes during inventory acquisition.

• Cycle Count for Inventory:

Accuracy retention and mismatch recognition is planned and executed.

• Bin Organization:

Allocate specific bin locations for improved inventory arrangement and picking efficiency.

• Supply Chain Connection:

NetSuite Inventory Management has an extensive supply chain connection, as it links with supply chain planning, manufacturing, procurement.

• Reporting And Analytics:

For example, one can employ real-time analytics in the form of dashboards, track KPIs such as costs, turns among others that present customizable reports about the state of stock as well as other vital business metrics.

• Flexibility And Scalability:

NetSuite is scalable to support business growth since it is cloud based.

How NetSuite helps with Inventory Management

NetSuite provides real-time visibility into inventory across locations from a centralized platform. It automates replenishment using demand forecasting to optimize stock levels. Features like lot/serial tracking enhance traceability. NetSuite employs strategies like ABC analysis and EOQ modeling to reduce carrying costs. It accurately calculates true landed costs. Mobile barcoding supports efficient cycle counting and warehouse management. Integrated with supply chain processes for end-to-end coordination. Provides real-time analytics and reporting on inventory KPIs. Cloud-based for scalability and flexibility.

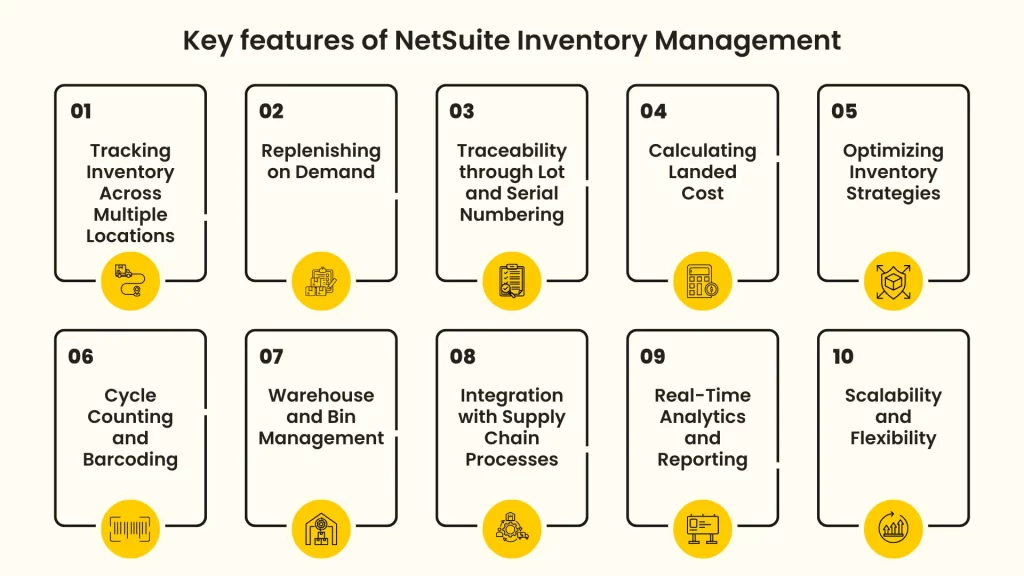

Key Features of NetSuite Inventory Management

1. Tracking Inventory Across Multiple Locations:

Track inventory levels, costs, and availability in several areas, subsidiaries, and distribution centers from a centralized hub.

2. Replenishing on Demand:

Use demand forecasting to auto-recommend the replenishment that is needed to keep stock at the optimum level.

3. Traceability through Lot and Serial Numbering:

Create the traceability of lot numbers; expiry dates; and serial numbers.

4. Calculating Landed Cost:

Include duties, taxes, shipping and other acquisition costs in order to find out the true landed cost of inventory.

5. Optimizing Inventory Strategies:

Techniques such as ABC analysis, economic order quantities (EOQ), and just-in-time (JIT) inventory management can be employed by businesses.

6. Cycle Counting and Barcoding:

Techniques for the support of efficient inventory management through cycle counting, bar coding and linking with mobile equipment.

7. Warehouse and Bin Management:

8. Integration with Supply Chain Processes:

9. Real-Time Analytics and Reporting:

Provides access to real-time dashboards, KPIs, and customizable reports on inventory status, costs, and turns.

10. Scalability and Flexibility:

Cloud-based solution that can increase or decrease its size in line with changing business needs.

Frequently Asked Questions (FAQs)

It includes costs like duties, taxes, shipping and other acquisition expenses in addition to the purchase price to accurately calculate the total landed cost per inventory unit

It includes costs like duties, taxes, shipping and other acquisition expenses in addition to the purchase price to accurately calculate the total landed cost per inventory unit.

It seamlessly integrates with NetSuite’s procurement, manufacturing, and order fulfillment solutions for end-to-end coordination.

Real-time dashboards, KPIs, and customizable reports on inventory status, costs, turns, and related metrics across locations are available.

It supports standard costing, average, FIFO and LIFO costing methods based on accounting standards and business requirements.