- February 20, 2025

- Nilesh Sanura

- 0

Optimize Your Warehouse Operations with NetSuite WMS

In today’s fiercely competitive business landscape, getting your warehouse management in line is essential to keep your business profitable and your customers happy, all while ensuring smooth supply chain operations. Warehouses form the backbone of various sectors: retail and e-commerce, manufacturing, distribution, and so on. Modernizing workflows and operational efficiency is what companies need today, and all of this can only be achieved through a sustainable warehouse management system (WMS).

NetSuite WMS (NetSuite cloud-based ERP): This comprehensive warehouse management system is designed specifically for NetSuite customers. It also provides businesses with top-down visibility and control of all aspects of their warehouse. NetSuite WMS offers an all-in-one solution for inventory tracking, order fulfilment, shipping, financial monitoring and reporting on a single platform, tied in with warehouse management to overarching enterprise resource planning (ERP).

What is a Warehouse Management System (WMS)

A warehouse management system (WMS) is a type of specialized software designed to optimize and automate warehouse operations. It enables accurate stock tracking, order processing, and stock-level management, minimizing errors and streamlining operational costs. Businesses can simplify workflows through automation and efficient operations for receiving, storing, picking, packing and shipping goods.

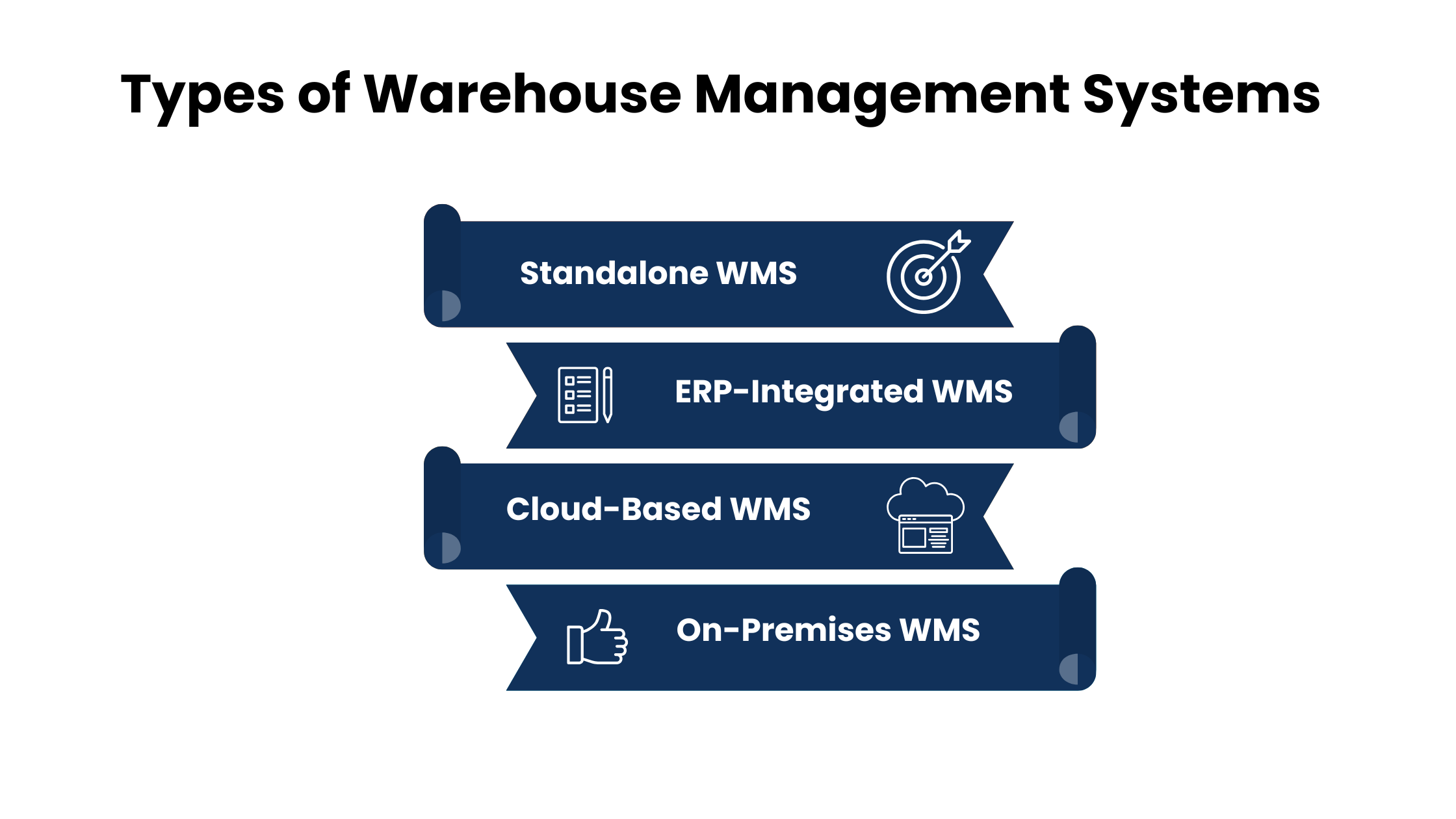

Types of Warehouse Management Systems

Featuring varying capabilities tailored to distinct operational challenges, different WMS solutions suit specific businesses across sectors.

- Standalone WMS: Primarily targets warehouse management, managing inventory tracking, picking and packing. Ideal for small to mid-tier businesses with few integrations.

- ERP-Integrated WMS: Offers integration with an ERP system for complete business visibility. This includes NetSuite WMS, which provides real-time coordination between departments.

- Cloud-Based WMS: Provides remote access and is ideal for businesses with multiple warehouses and distribution teams. NetSuite WMS leverages the cloud for scalability.

- On-Premises WMS: Generally, we have an in-house installation with more control over security and data. Used by enterprises with mature IT infrastructure but comes with high cost

NetSuite WMS is a solid option for businesses looking for a warehouse management system that integrates with an ERP in the cloud.

Advantages of NetSuite WMS

NetSuite WMS distinguishes itself through its comprehensive integration with NetSuite ERP, allowing companies to enhance warehouse operations while maintaining alignment with inventory, accounting, and customer management systems.

Some of the key benefits of NetSuite WMS are:

- Unified Platform: Allows integration with ERP, CRM, e-commerce, and procurement for end-to-end operational efficiency.

- Cloud-Based Flexibility: Enables real-time warehouse data ingestion without requiring any manual processes to be performed.

- Scalability: Evolves with business expansion, new fulfilment centers, and expanded stocking needs.

- Customizable Workflows: Enables businesses to customize picking strategies, replenishment rules, and warehouse layouts to meet specific requirements.

- Real-Time Data & Reporting: Provides real-time dashboards to gain insights into inventory levels, order statuses, and warehouse performance.

NetSuite WMS Functionality

Essential warehouse operations in NetSuite WMS include:

- Inventory Intake & Storage: Update inventory in real-time with barcode scanning, reducing manual mistakes.

- Inventory Management & Replenishment: RFID, barcode scanning, and automated cycle counting ensure stock levels are accurate.

- Order Fulfilment: Optimized picking strategies (wave, batch, and zone picking) make sure your orders are sent fast and error-free.

- Shipping & Returns: Connects with shipping carriers to create labels automatically and rapidly handle returns.

Key Features

1. Advanced Picking Strategies

- Wave Picking: Batches similar orders to optimize routes for picking.

- Zone Picking: Establish Zones within the Warehouse

- Batch Picking: Group orders of similar items together to minimize the need to make the same movement multiple times.

2. Real-Time Inventory Tracking

- RFID & Barcode Scanning: Ensures accurate stock visibility.

- Cycle Counting: Helps maintain an accurate inventory check without the physical count of all the data.

- Lot & Serial Number Tracking: Keeps products in compliance and can be traced through supply.

3. Automation & Mobile Access

- Automated Replenishment: Helps to avoid stock shortages and surplus.

- Mobile Access: Mobile device access to real-time data for warehouse staff.

- Dashboards and Reports in Real-Time: Provide operational insights for strategic decisions

Benefits of NetSuite WMS

The benefits of using NetSuite WMS are several:

- Increased Accuracy: Automated systems minimize manual errors.

- Faster Order Fulfillment: Picking and packing optimization accelerates delivery speeds.

- Better Inventory Visibility: Real-time tracking prevents stock shortages.

- Scalability: Accommodates business growth and multiple warehouse operations.

- Cost Savings: Automation decreases operational costs.

Challenges Addressed by NetSuite WMS

Key challenges that NetSuite WMS forces include:

- Inventory Inaccuracy: Constant tracking mitigates discrepancies in inventory.

- Inefficient Order Processing: Automated picking and fulfillment make operations more efficient.

- Lack of Visibility: Real-time dashboards help us to make better, more informed decisions.

- High Operational Costs: Automation saves on labor and processing costs.

Pricing & Implementation Costs

Cost factors to consider when implementing NetSuite WMS include:

- Software Licensing: Subscription pricing varies by business size and needs.

- Implementation Costs: Setting up, system integration, and training staff.

- Support & Maintenance: Ongoing support for smooth operations and updates

While the initial investment can be high, automation, accuracy, and efficiency often result in overall lower costs on the return on investment scale.

Conclusion

NetSuite WMS transforms warehouse operations and offers an integrated solution for real-time warehouse management and fulfilment processes, improving inventory accuracy and increasing productivity. Advanced automation, real-time tracking, and effortless integration with NetSuite ERP help streamline operations, optimize business processes, and scale rapidly. With NetSuite WMS, you get the tools you need to thrive, whether you’re operating a retail, e-commerce, manufacturing, or distribution business in today’s ever-hastening market.

Ready to deploy NetSuite WMS for your business? Don’t worry; our experts at Livestrong Technologies have your back! NetSuite WMS Solution Implementation, Customization, & Support We ensure smooth implementation, customization, and ongoing support so that you get the best out of NetSuite WMS. Contact us now and learn about the benefits of optimizing your warehouse management today!

Frequently Asked Questions (FAQs)

NetSuite WMS is a cloud warehouse management system that is part of your NetSuite ERP, allowing businesses to automate the tracking of inventories, the fulfilment of orders, and the efficiency of warehouses. It minimizes errors, enhances visibility and smoothens operations to work efficiently.